Double porosity filtration (DPF)

Double porosity filtration (DPF) has been developed to clean water contaminated by fine particulate material and dissolved substances. Based on adsorption-sedimentation technology, the treatment process uses no polymers, precipitants or other chemicals. A hydraulic gradient of 10% is established by placing the outflow lower than the inflow, causing gravity to force the water through a filter. Any energy consumed relates solely to the transport of water to and from the facility. The method can be adapted to densely built-up urban districts as it can be placed underground or incorporated into a square or other paved surface. The treated water can be used for recreational purposes in the city. Double porosity filtration could also be used to protect the receiving water, for example, where contaminated run-off is to be discharged to a sensitive receiving water. The method’s ability to treat the water that flows off roads (‘road run-off’) is currently being tested at a pilot facility in Byparken in ěrestad, Copenhagen. (Read more under the description “Double porosity filtration in ěrestad”). A development project focusing on product maturing is currently underway, with financing provided by the Danish Ministry of the Environment.

Players

Double porosity filtration has been developed as part of a collaboration between the former K°benhavns Energi, CPH City & Port Development, City of Copenhagen, Realdania, Ramboll and the University of Copenhagen. The university has applied for a patent for the method (PCT/DK2003/000443, priority date 26 June 2002), and its Tech Trans unit is handling the commercialisation of the technique. A broad-based innovation group has been attached to the current development project (see below).

Mechanism

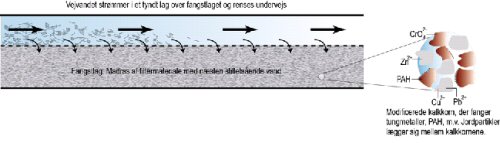

A double porosity filter has a filter with two porosities, high and low. It has a dual-layer structure, with a high-porosity layer laid over a low-porous layer containing a suitable filtering material (see figure 1). The high-porosity layers are flow layers while the low-porosity layers are “capture” layers in which there is essentially no flow. Water flows horizontally through the high-porosity layers and can be visualised as a sheet of water flowing over a mattress of filtering material. The water in the high-porosity layers flows unhindered over the filtering material in the low-porosity layers, and is treated in the process. The primary treatment mechanisms are gravity-driven particle sedimentation and the adsorption of dissolved contaminants to natural materials. With DPF, the flow routes are thus separated from the layers that withhold suspended substances. This prevents the filter from clogging, and in principle the entire treatment capacity can be used up before the filter has to be re-generated. Stacking several “sandwiches” on top of each other and making them wider means a larger inflow area can be created and thus a higher hydraulic capacity. Making the filter longer results in cleaner water and longer lifetime.

Figure 1: Illustration of the sandwich structure used in double porosity filtration. The dirty water flows horizontally into the filter, mainly via the high-porosity layer, whose hydraulic conductivity is many times higher than that of the low-porosity capture layer containing filtering material. During the time it takes for the water to travel from the inlet to the outlet, the contaminants are deposited on the underlying low-porosity layer. At the 50-m long pilot facility in ěrestad, the flow-through time is approx. one hour in the six-layer version and approx. two hours for the 18-layer version. The thinness of the flow layers (6 mm in the six-layer version and 4 mm in the 18-layer version at the ěrestad plant) makes for effective sedimentation – the particles only need to fall a few millimetres before landing in the catch layer. Here the particles get trapped between the grains of filtering material, which therefore must have a certain porosity. The limestone used in the ěrestad pilot plant has 50% porosity. Dissolved contaminants can be withheld in the filter through adsorption to the surface of the filtering material. This happens when the water flow passes the compounds close across the surface of the filtering material. Obviously the chosen filtering material must have an affinity for the substances. After a rainfall event, the filter drains off. The remaining moist, aerated filter remains provides conditions for the decomposition of organic materials.

Testing

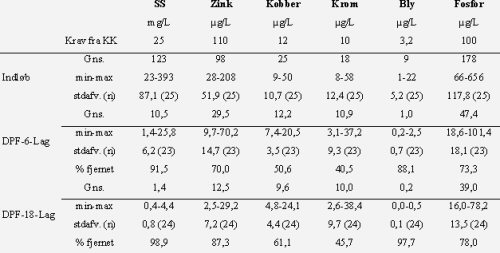

Twenty-five rainfall events sampled from 15 January—26 July 2007 have been analysed at the ěrestad pilot plant. The inlet water for every rainfall event was analysed and compared with the pollutants in the outlet water from DPF-6 and DPF-18. Both filter versions treat the water satisfactorily according to the concentrations set by the City of Copenhagen for the use of treated water in the canals of ěrestad (table 1). DPF-18 has an exceptionally high retention of the suspended solids zinc and lead. The full report (basic report, in Danish) can be downloaded from the link at the bottom of the page.

Table 1: Results of double porosity filtration trial. SS = suspended solid. The concentrations of zinc, copper, chrome, lead and phosphorus are stated as total content (both dissolved and particulate bound). Gns = average concentration for the 25 events. Min-max = lowest and highest concentrations among the 25 events. Stdafv = Standard deviation. (n) = number of events on which the average is based. % fjernet (removed) = average outlet concentration as a percentage of average inlet concentration. KK stands for City of Copenhagen.

|

In addition to the parameters in table 1, the 25 events were analysed for a number of other factors, including environmentally harmful organic compounds, other elements, breakdown by dissolved and particulate form, breakdown by particle size, correlation between suspended solids and heavy metals. These data can be found in the supplementary report in Danish (see the link at the bottom of the page). This report shows that most of the particles entering the treatment plant (after sludge trap and oil separator) are less than 30 Ám in diameter and half are less than 5-8 Ám. The plant appears to remove particles down to colloid size (1-2 Ám). The full report

In the winter of 2007-2008, a coating was applied to DPF-6 to improve its ability to remove chrome and copper. The effect of the coating was tested first by adding solutions of chrome, copper and arsenic directly into the inlet while clear water was recirculated (outlet water recirculated to the inlet) and then monitoring the concentrations on the outlet side. The effect was then tested by sampling and analysing 17 rainfall events in the second half of 2008, where the treatment efficiency was examined in the same way as for the first 25 events. The test results are being prepared and will be published in a coating report.

Further development

Based on these results, a grant has been awarded for the further development of DPD; see the article from the Technical and Environmental department of City of Copenhagen and an article published in the national daily Jyllandsposten. In its wastewater plan for 2008, City of Copenhagen earmarked DKK 20 million to build a sewage treatment plant for cleaning road run-off from a catchment area in ěrestad of 30 reduced hectares. The wastewater plan offers a possibility for basing this plant on double porosity filtration.

Date

Description prepared/updated on 14 May 2009.

Contact person

Name: Senior researcher, Marina Bergen Jensen

Organisation: Forest & Landscape, Faculty of Life Sciences, University of Copenhagen, Rolighedsvej 23, DK-1958 Frederiksberg C

E-mail: mbj@life.ku.dk

Phone: +45 35 33 17 97

Read more about double porosity filtration her (in Danish).